Scale prediction is Scale Consult's core expertise. Since 2012, we have conducted more than 100 scale prediction studies for oil and gas operators and service companies worldwide, covering new field developments, well tie-ins, field expansion projects, and operational troubleshooting. Our studies range from single-well assessments to comprehensive full-field analyses with multiple wells and complex topside processes, addressing both snapshot production cases and full field-life scenarios.

What is scale?

Scale is the formation and deposition of solid minerals on production system surfaces—inside tubing, chokes, valves, heat exchangers, and other equipment. Scale can restrict flow, reduce heat transfer efficiency, cause equipment failure, and in severe cases, halt production entirely.

Common scale types include:

Sulfates: barite (BaSO₄), celestite (SrSO₄), anhydrite (CaSO₄)

Carbonates: calcite (CaCO₃), siderite (FeCO₃)

Sulfides: iron sulfide (FeS)

Chlorides: halite (NaCl)

Why Does Scale Form?

Scale forms when dissolved minerals in produced water exceed their solubility limits and precipitate as solids. Three main mechanisms trigger this:

Pressure and temperature changes When fluids move from reservoir to surface, pressure drops and temperature changes can reduce mineral solubility, causing carbonates (CaCO₃, FeCO₃) and sulfides (FeS) to precipitate.

Mixing of incompatible waters When formation water mixes with injection water (typically seawater), incompatible ions combine to form insoluble minerals—the primary cause of sulfate scales (BaSO₄, SrSO₄, CaSO₄).

Water evaporation Large pressure drops can cause water to evaporate into the gas phase, concentrating dissolved salts until they exceed solubility limits and precipitate as halite (NaCl).

Input data

The data needed for a scale prediction study will vary, but typical input data include:

Formation water composition and injection water composition (when relevant)

Reservoir fluid composition and lift gas composition (if relevant)

Flow rates

Pressure and temperature in reservoir and at relevant locations such as bottom hole and wellhead

Topside process description and conditions in separators, scrubbers, etc. (if topside is to be included in study)

Scale prediction studies

Oil and gas fields vary significantly, from shallow reservoirs with low pressure and temperature to HPHT fields with pressure up to 2000 bar and temperatures up to 200°C. Reservoir fluids can range from dry gas to heavy oil, and formation waters can vary in salinity from near-freshwater to NaCl-saturated brines. Fields can have seawater injection for pressure support, lift gas injection, and may range from single wells to platform wellheads or subsea templates where production from several wells mixes and flows through subsea flowlines to a process unit.

No two scale prediction studies are therefore identical—both input data and simulation setup must be tailored to each field and case.

Scale Consult can perform all types of scale studies for oil and gas wells and topside processes.

If you need to evaluate the scale risk for a new or existing field, please contact us for an informal discussion about how Scale Consult can assist you.

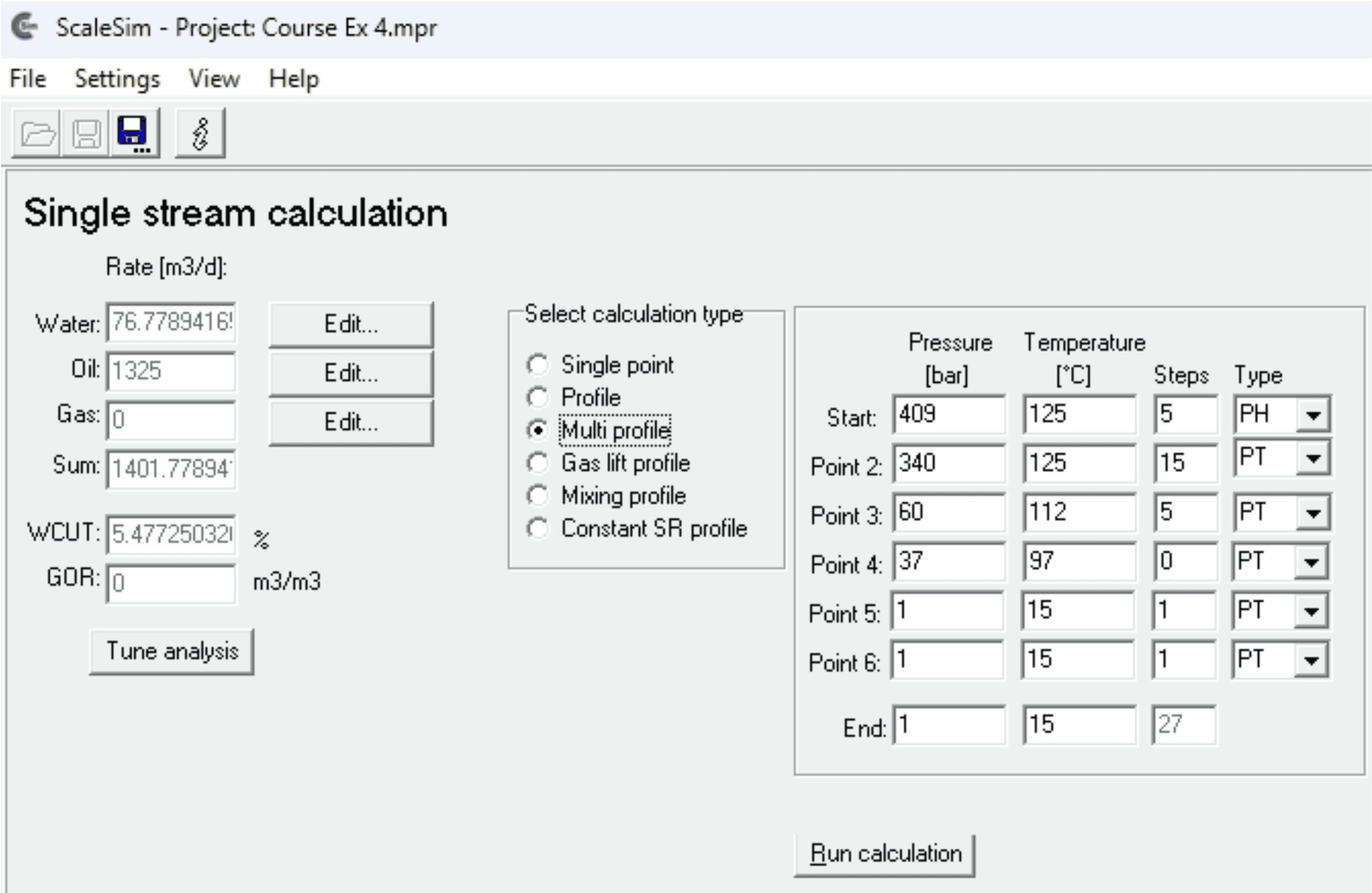

Complex scale prediction profile from reservoir to separator.

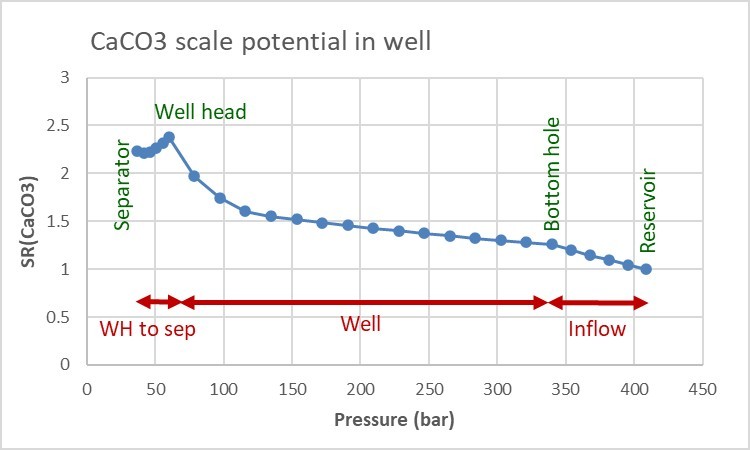

Calculated CaCO3 scale potential from reservoir to separator.

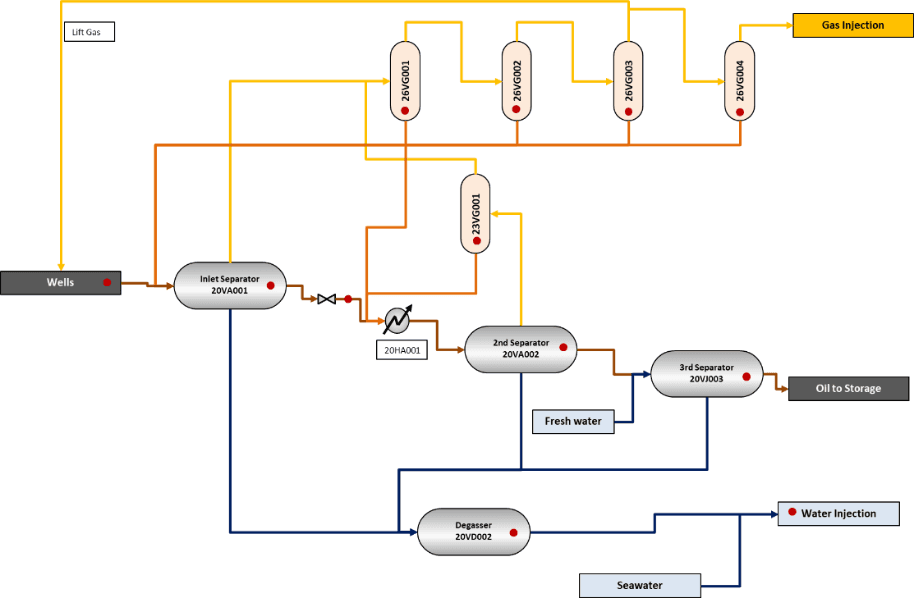

Varying CaCO3 scale risk in a topside process over time – simulations based on expected production profile and topside conditions.

Modelling scale risk in a topside process.