HalOpT is a Halite Optimisation Tool to monitor halite (NaCl) scale risk in oil and gas wells, and to optimise water injection to prevent halite formation. HalOpT can be run as a standalone model from Excel, or it can be implemented as an online tool.

Why halite forms

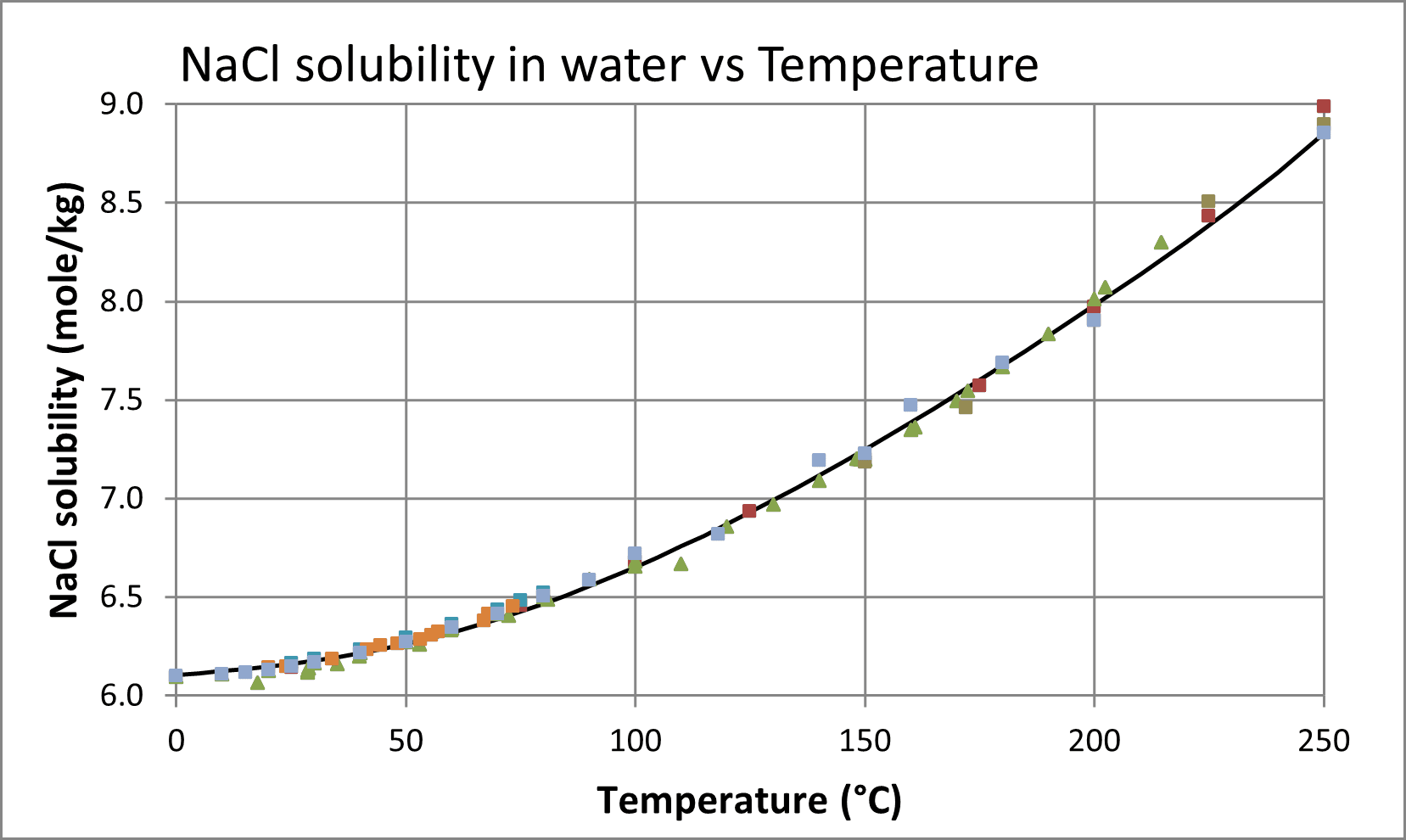

Halite is sodium chloride (NaCl), also known as table salt, and is the main component in most formation water. Some reservoirs may in fact contain formation water that is saturated with halite, or very close to. When a halite-saturated water is exposed to a reduction in pressure and temperature on the way from reservoir to surface, the solubility of halite decreases (see figures) and this will lead to formation of halite. Due to its high solubility, the mass of halite can easily reach several hundreds of kg per day if it starts to form.

Another factor that can also produce halite is if a well is produced with a high drawdown. The pressure drop from reservoir and into the well results in water evaporation and when there is less liquid water present to keep salts in solution, halite and other scale types can form.

A very effective way to prevent formation and also to remove halite is by injection of freshwater or low-salinity water. HalOpT an help operators to optimise this water injection such that it is sufficient to prevent halite, but not excessive.

Solubility of halite vs temperature and pressure – experimental data and ScaleSim model.

The HalOpT Model

The HalOpT model is based on the ScaleSim thermodynamic model and is designed to model flow of high-salinity water together with oil and/or gas from a reservoir, including lift gas when relevant, to the surface facility (manifold or inlet separator). HalOpT will calculate halite saturation and also calculate optimum wash water injection to keep halite saturated below a user-given maximum level. HalOpT also calculates chloride concentration along the well path, and user may choose to optimise water injection to an upper chloride limit.

The user must specify composition of formation water and the wash water, reservoir fluid composition and lift gas composition (when relevant)

Example of formation water and wash water compositions.

Example of formation water and wash water compositions.

HalOpT Simulations

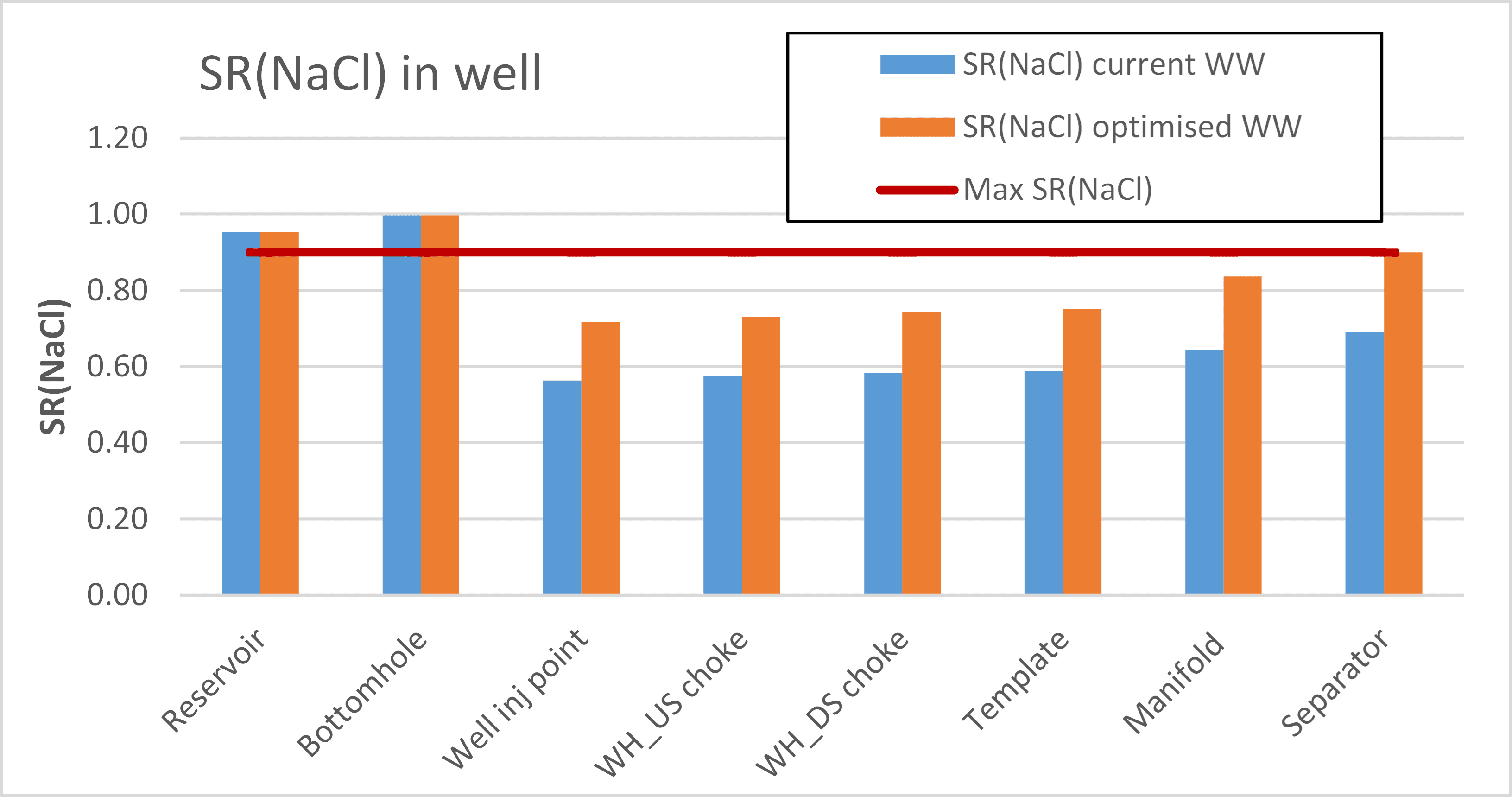

The figure shows an example of a simulation in the Excel version of the tool. A well is producing 980 Sm3/d oil and 140 Sm3/d produced water (formation water + condensed water + injected wash water). Pressures and temperatures along the well are specified. The wash water injection point is point no 3 and the current water injection rate is 23 Sm3/d. The maximum SR(NaCl) can be specified for each location, in the example it is set to 0.9.

The graph shows calculated SR(NaCl) with current wash water injection (blue bars) and shows that after the injection point, SR(NaCl) is well below the maximum limit. The wash water injection rate can therefore be reduced from the current 23 m3/d down to 13.4 m3/d and this will increase the SR(NaCl), but not above the limit (orange bars). This will save about 10 m3/d of injection water.

Example of formation water and wash water compositions.

HalOpT online

HalOpT can be run as an online model, either by running the Excel version or by connecting a dll-version of HalOpT directly to the control system or another production surveillance system. Based on production data, flow rates, pressures, temperatures etc., HalOpT can calculate saturation state in the well and optimised wash water injection rate – which can be fed back to the control system.